The 6 requirements of effective analog layout automation

Analog Layout remains a time consuming manual task to most layout designers. For as long as integrated circuits have existed, designers have been manually placing individual transistors, drawing every shape and guard ring, and routing every wire by hand. Digital layout automation on the other hand, became almost completely automated. As early as the mid 1980’s EDA pioneers at Tangent Systems allowed digital blocks with 100s of millions of devices to be routinely placed and routed in a few hours with almost no human input, having an enormous impact on digital design productivity.

In 1985, Intel debuted the 80386 microprocessor which contained 275,000 transistors on the die and in 2020 Apple released its first homegrown microprocessor, the M1, which includes 16 billion transistors – In just 35 years, Apple’s latest device contained over 58,000 x more transistors than its ancestors! It is probable that the 80386 was primarily designed by hand, but it is inconceivable that humans were involved in laying out even a tiny fraction of the transistors in Apple’s M1. The team behind the M1 was much larger than the original 80386 team, but the overall layout productivity is at least three orders of magnitude, i.e., 1000x, greater than it was in 1985.

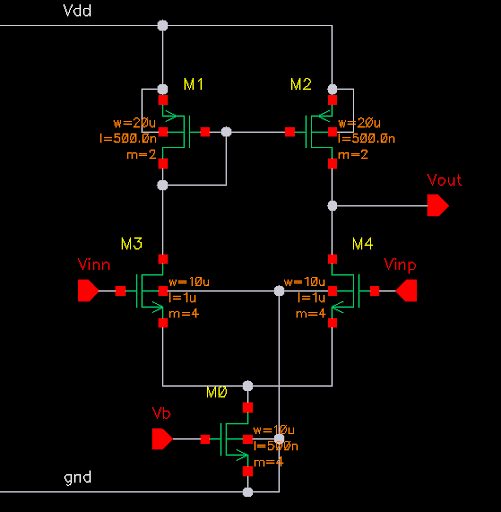

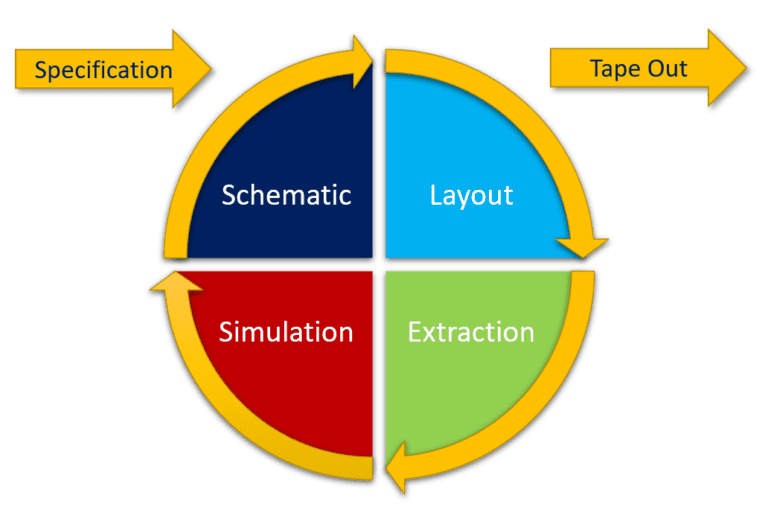

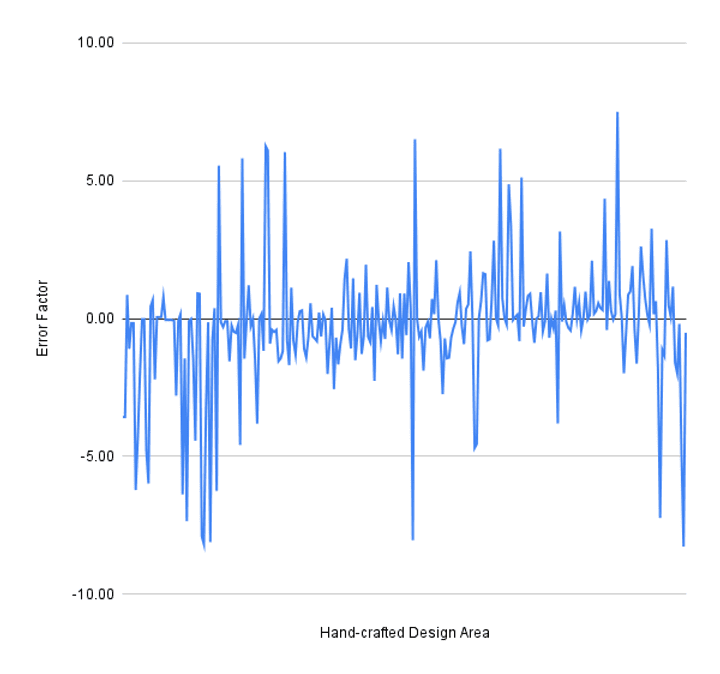

Over the same period, a number of incremental changes to the analog design flow have also increased layout productivity in this domain. These changes include parameterized cells, schematic-driven layout and more recently, templated layout. The total effect of these changes is perhaps as much as a 10x improvement, as a layout that in 1985 may have taken a designer three weeks to complete, can now be accomplished in 2-3 days!

However, process changes have also made analog design closure much harder. Today, layout dependent effects have become so vital that it is impossible to determine the optimum layout in advance. Engineers and designers often need to tweak and respin their design 4 or 5 times before meeting the specification with the effective increase in productivity is, in reality, 2-3x at most.

Analog layout has become stuck in an expensive and time-consuming loop between circuit engineers and layout iterations and the analog design community desperately needs a transformative technology that finally solves analog layout automation, just like Tangent and Tancell did for digital design in the 1980s, moving away from incrementally improving the existing manual layout techniques and truly delivering analog automation to prevent analog designers from forever repeating the mostly thankless manual layout tasks.

To close the growing analog productivity gap there are some essential requirements that need to be considered:

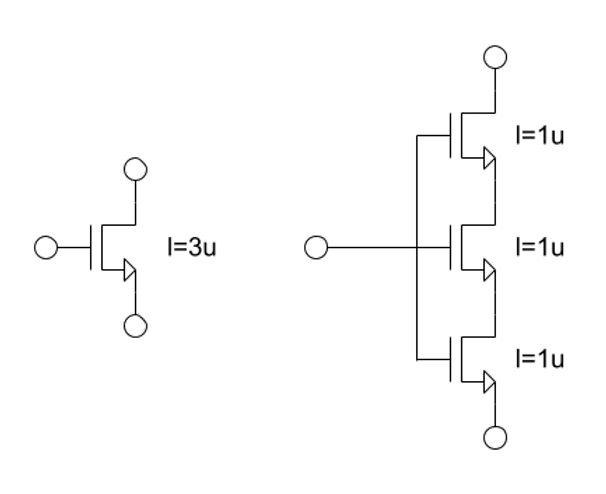

- Analog circuit recognition: The tool must know and understand many analog circuit structures and be able to recognize them when they appear in the circuit being worked upon.

- Automatic constraints: After understanding the circuit, the tool needs to produce appropriate constraints for itself, without the need for engineers to spend hours editing them.

- Analog layout strategies: The tool must have many tried and tested layout strategies built-in to its algorithm, linking the layout to the circuit understanding and constraints.

- Deep design rule compliance: A true understanding of the design rules deep in the core of the algorithm. The tool must not just have the ability to check for errors but the ability to avoid creating them in the first place.

- Flexibility: Analog design is difficult, hard, and fast “rules” about layout style will fail as often as they succeed. Rigid adherence to constraints produces poor quality layout. A successful analog automation tool needs the intelligence to be flexible where required to achieve a good result.

- Easy to use: The analog design flow is already complex; any new tool in the flow must make the engineer’s role easier, not harder.

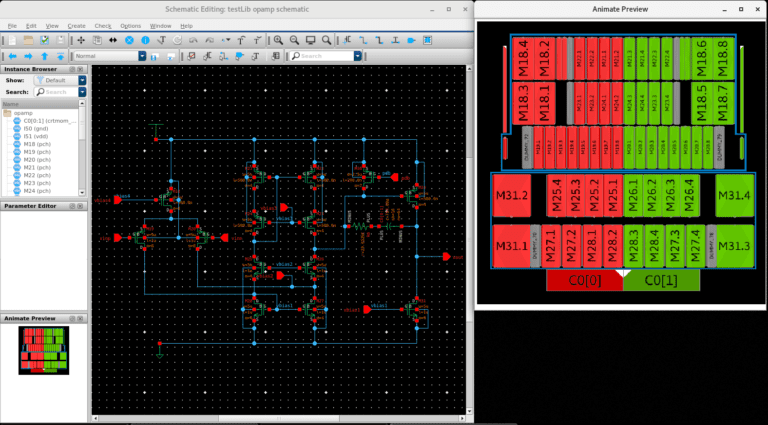

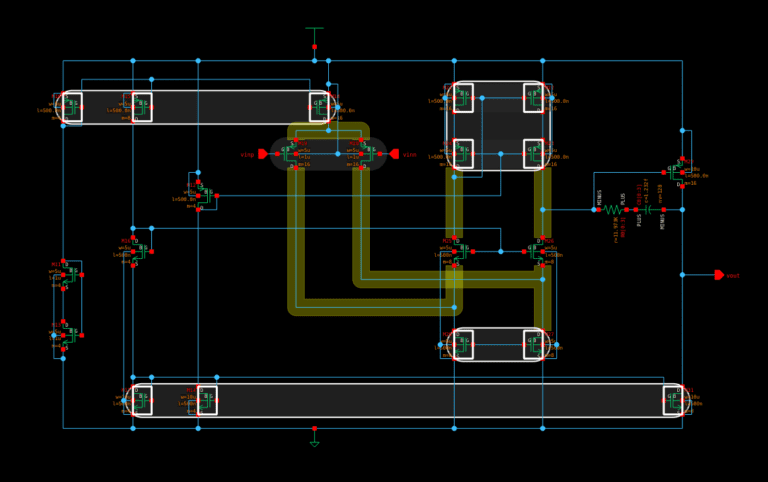

At Pulsic, we have been working hard to close this gap by developing an exciting new tool, Animate Preview, that tries to encompass all of these attributes, as well as integrating into the circuit engineer’s schematic environment by automatically creating a layout preview for the circuit whilst the engineer is still editing their schematic, giving them fast feedback on design decisions! It has allowed us to remove the previously discussed problem of generating constraints for the circuit, as Animate Preview understands analog circuit topologies and automatically generates appropriate constraints for the circuit and routing many critical structures in the layout preview, overall eliminating the layout loop between circuit engineers and layout iterations and improving productivity!

If you’re interested in hearing a more in depth discussion about the requirements needed to close the growing analog productivity gap and how we hope to address these requirements with our new Animate Preview tool you can book a demo here.

You can also find webinars about Animate Preview in our links page here.